News

How to Build a Gang Sheet

How to Build a Gang Sheet:

How to Remove Gang Sheet Background:

How Does DTF Transfer Film Work?

PerfecPressHTV provides high-quality DTF transfer printing that can transform your wardrobe, items such as mugs and backpacks, and much more. It is...

The Complete Guide to DTF Printing: From Setup to First Print

To start DTF printing, you'll need a few key items: an Epson L1800 printer, special DTF inks, PET films, a heat press, and DTF powder. Keep your wo...

How Do Custom DTF Transfers Work?

Direct to film printing has really revolutionized the clothing and advertising industries for a number of reasons. No longer do individuals and bus...

Starting a Custom DTF Transfers Home Business

A custom DTF transfer business is easy to start with little money upfront and can make good money. You'll need basic tools like a DTF printer, heat...

Siser Puff Vinyl Techniques for Beginners

Siser puff vinyl makes designs that pop up from clothing when heated. Start with basic designs and big letters, as these work best. Put the vinyl o...

Scaling Your DTF Transfers Business: Equipment and Workflow

Growing a DTF transfers business needs the right tools and a smart way of working. Get good DTF printers, the right inks, powder glue, and solid he...

Puff Vinyl Design Tips for Maximum Impact

To get the best results with puff vinyl designs, pick basic, bold shapes and leave enough room between parts so they don’t merge when heated. When ...

Puff HTV Design Ideas for Unique Apparel

Puff heat transfer vinyl makes clothes stand out by adding raised designs and layers. Use 100% cotton clothes that have been pre-washed for best re...

Mastering Puff Vinyl Effects for Custom Apparel

Puff vinyl makes designs rise up from fabric when heated, working best at 311°F (155°C). The vinyl sticks better to cotton or mixed cotton-polyeste...

Making Money With Custom DTF Transfers in 2024

Starting a DTF transfer business in 2024 needs about $3,000 to $20,000 to buy equipment, plus money for a workspace and basic supplies. You can mak...

DTF Transfers Ready To Press: Storage and Handling Tips

Store DTF transfers carefully to keep them in good shape. Keep them flat in sealed containers and watch the temperature - it should be between 60-7...

DTF Transfers Ready To Press: Production Timeline Guide

Making DTF transfers works best when you follow five main steps. First, set up your work area - keep it clean and put all tools where you need them...

DTF Transfers Printer Maintenance and Cleaning Schedule

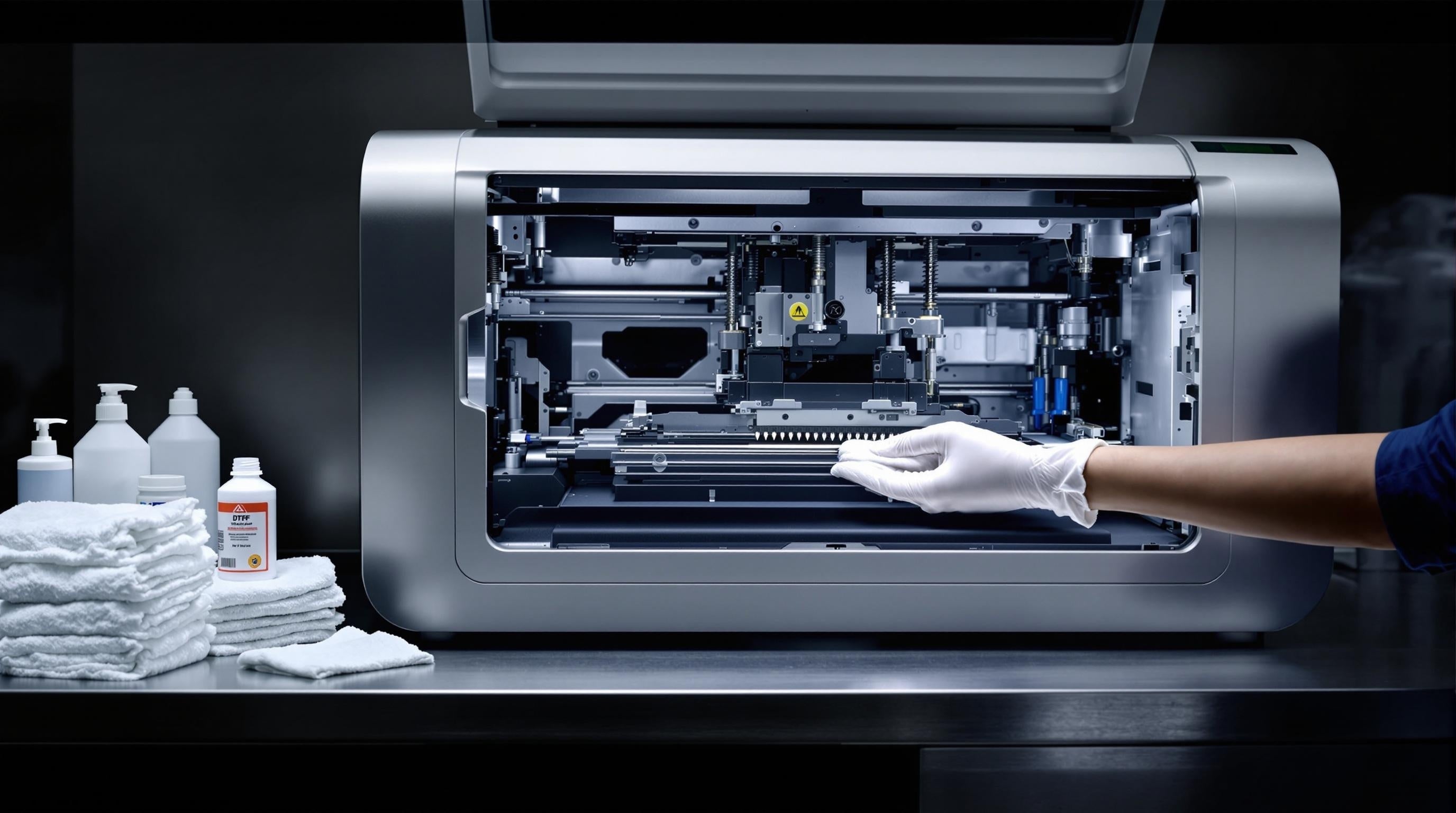

DTF transfer printers need regular upkeep on a daily, weekly, and monthly basis to work well. Each day, you need to shake the white ink bottles, cl...

DTF Transfer Printing Cost Analysis and Pricing Strategies

Starting a DTF transfer printing business costs between $1,700 and $12,000. The main equipment needed is a DTF printer ($1,500-$7,000) and a heat p...

DTF Transfer Printer Selection Guide for Beginners

Choosing a DTF printer as a beginner comes down to finding machines that are easy to use and well-built. Good starter models like the A4 L805 and A...

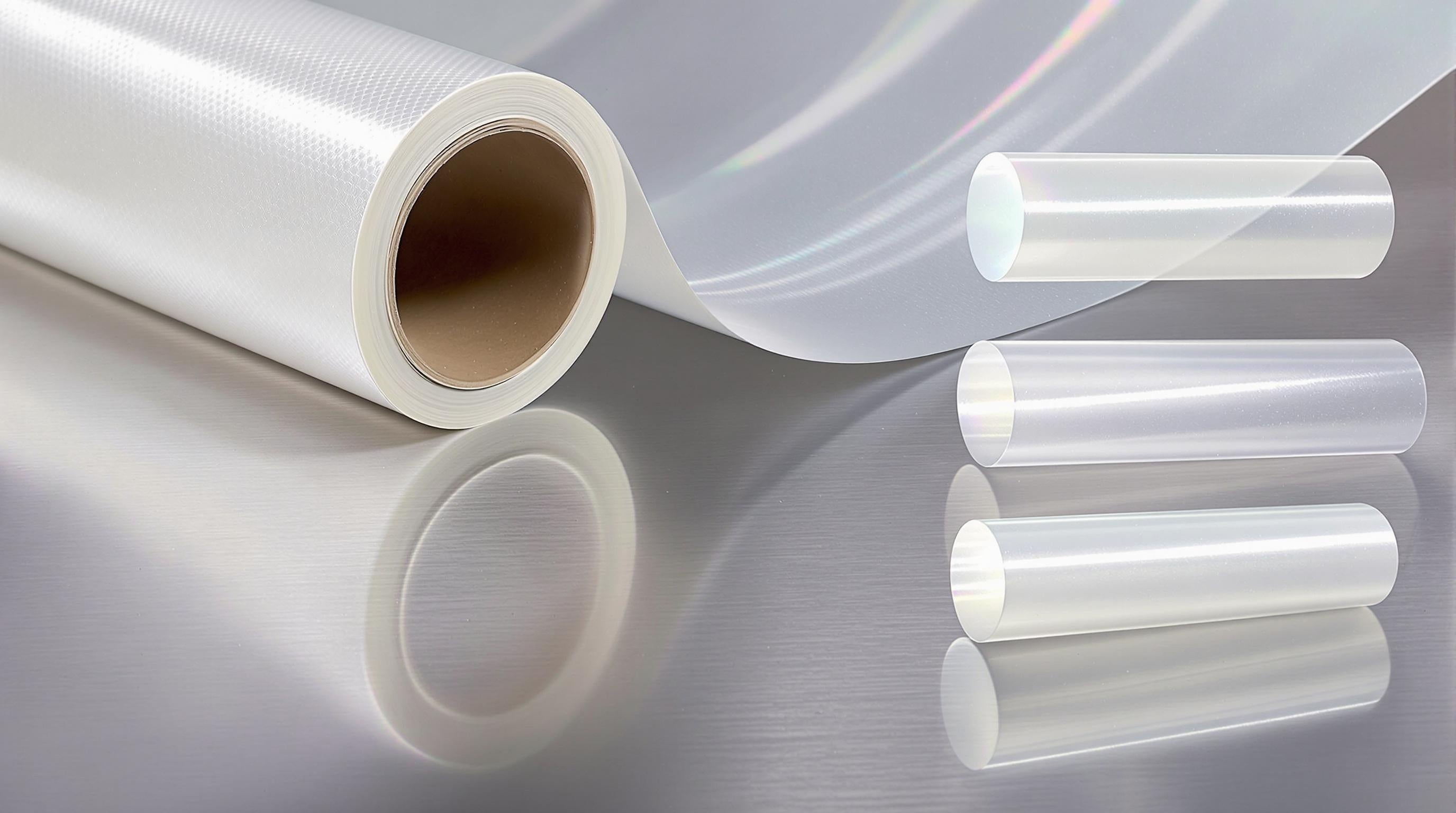

DTF Transfer Film Types and Their Best Applications

DTF transfer films come in four main types: cold peel, hot peel, matte, and glossy. Cold peel films need to cool down before you can take them off ...

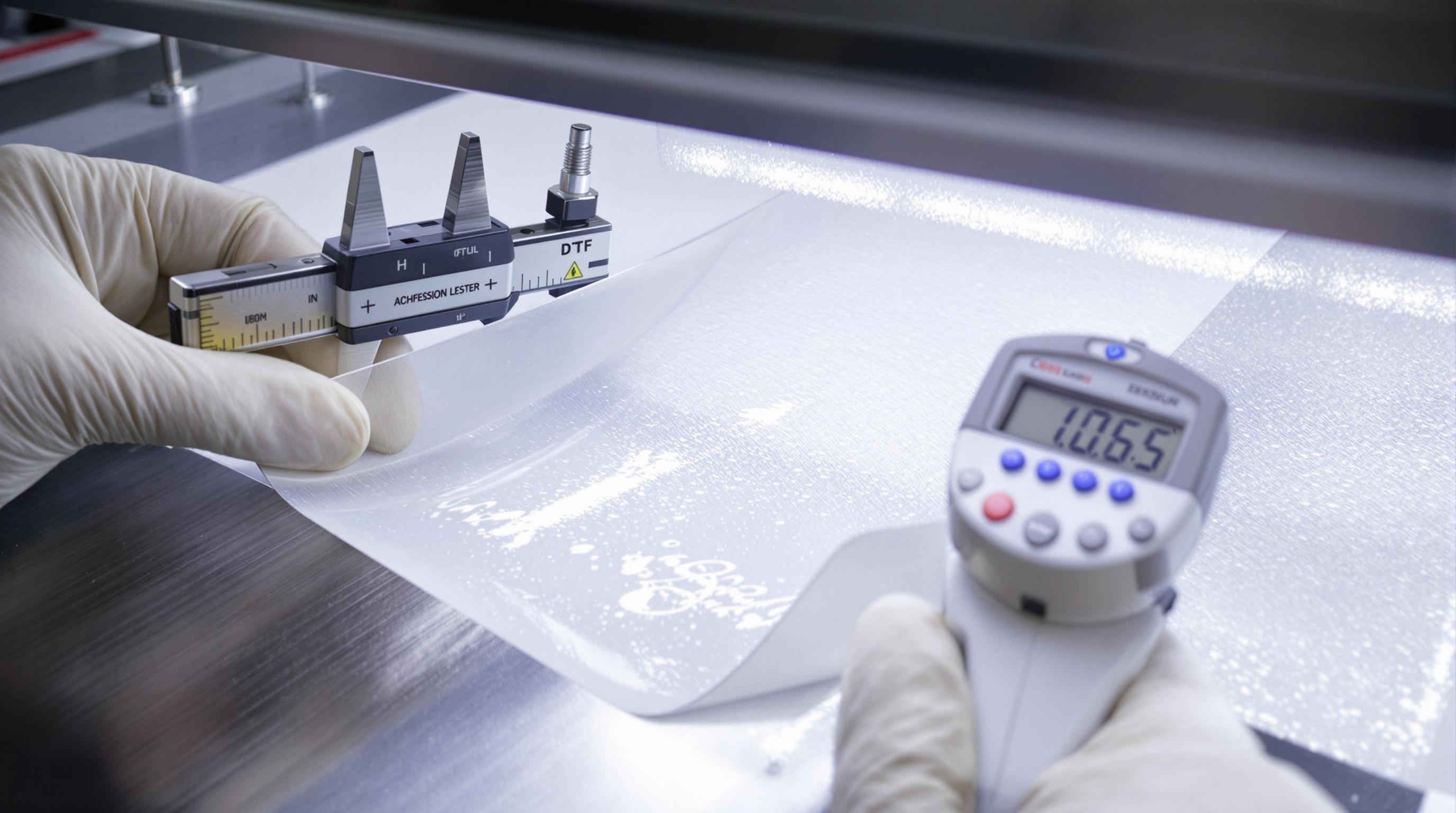

DTF Transfer Film Quality Control and Testing Methods

DTF transfer film testing needs careful checks of many important features. Looking closely shows any marks, scratches, or wrinkles on the film surf...

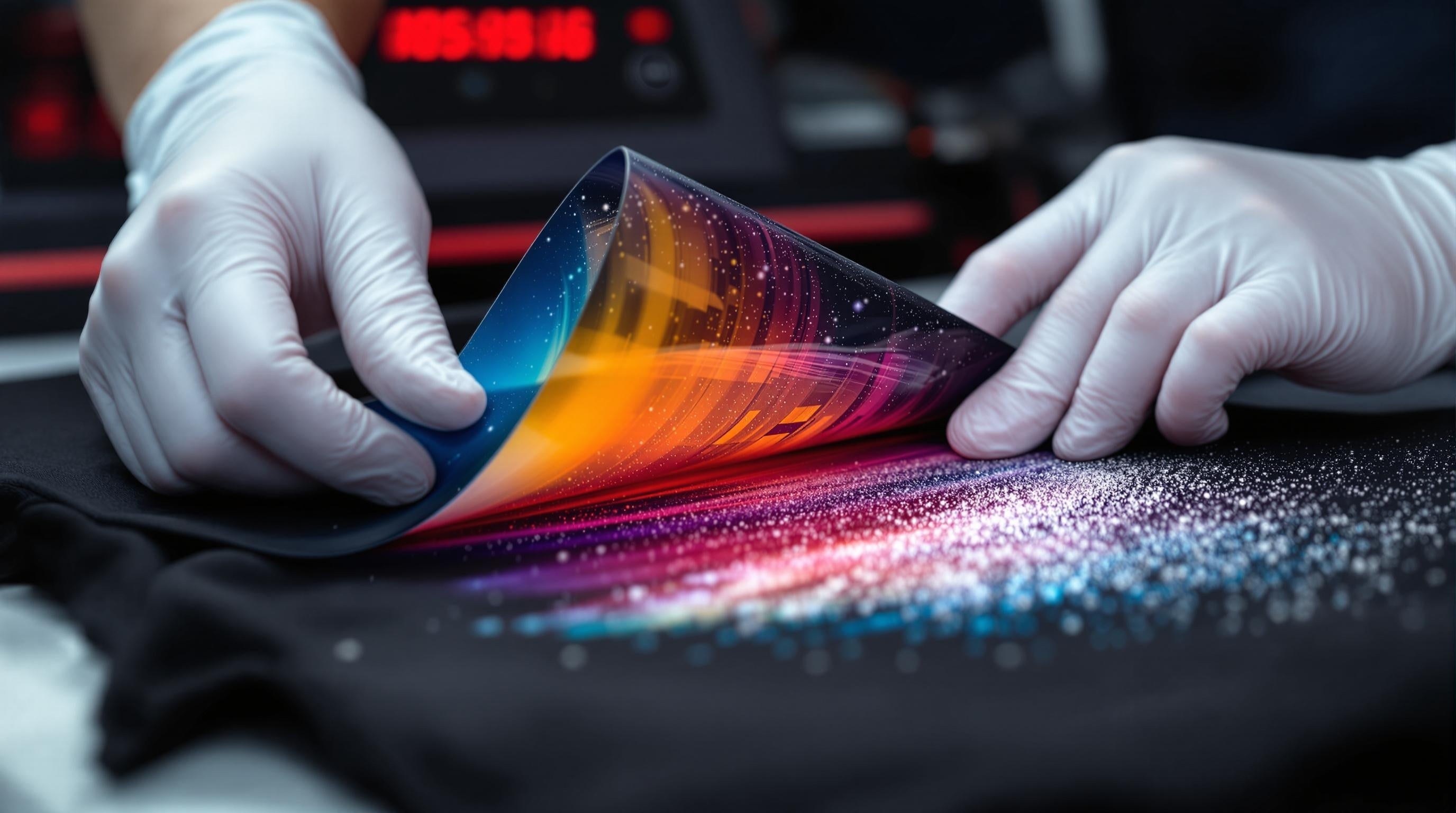

DTF Transfer Film Application Techniques Masterclass

To get great DTF transfer results, you need to keep your workspace at the right temperature (75-80°F) and humidity (55-75%). Use good-quality trans...

DTF Supplies Checklist: Everything You Need to Start

You need several key items to begin DTF printing. The main equipment includes a DTF printer (such as Prestige A3+), a heat press, and a powder shak...

DTF Printing Vs Screen Printing: a Business Comparison

DTF printing and screen printing work differently and each has its own benefits for businesses. DTF works best for small orders because it costs le...

DTF Printing Software and Design Tools Explained

DTF printing tools and design software help creators make high-quality artwork for film transfers. Popular choices include Adobe Illustrator for cr...

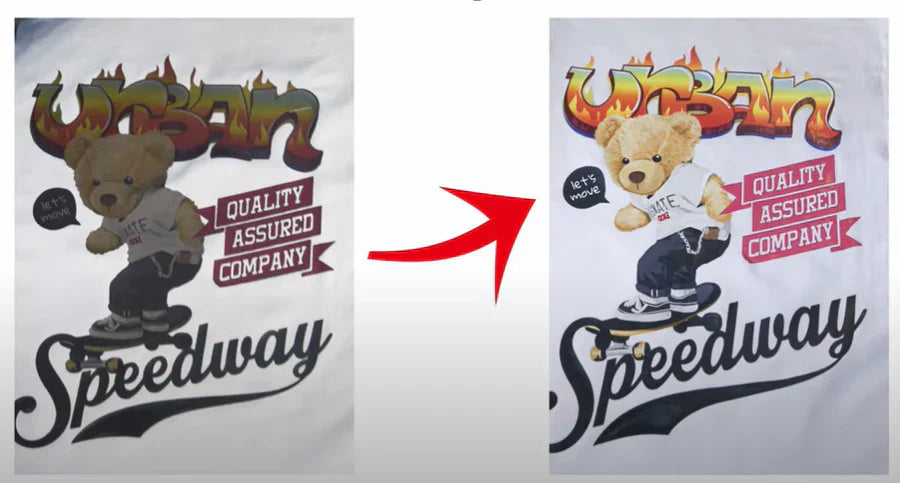

DTF Printing on Dark Garments: Best Practices Guide

Printing on dark clothes with DTF needs careful steps to work well. Use clear, sharp artwork files with at least 300 DPI in CMYK colors. Put down a...

DTF Printing for Print on Demand Businesses

DTF printing helps print-on-demand businesses make great transfers on many types of fabric without needing to treat them first. It works by printin...

DTF Heat Transfer Temperature and Time Settings Explained

DTF printing works best when you heat it to 300-320°F. Start with a quick 2-3 second press to get rid of moisture, then press again for 12-15 secon...

DTF Heat Transfer on Different Fabric Types

DTF heat transfer works well on many types of fabrics by using special film and heat-sticky glue. Natural fabrics like cotton work great and hold c...