DTF transfer printers need regular upkeep on a daily, weekly, and monthly basis to work well. Each day, you need to shake the white ink bottles, clean the print heads, check if the nozzles are working, and make sure there's enough ink. Every week, check the filters, adjust the color settings, and look over the moving parts. Once a month, do a deep clean of the inside parts, update the printer software, and check the whole system carefully. You'll need simple cleaning items like alcohol, soft cloths, cotton swabs, and canned air. Keep track of what you do in a log book to spot any problems early and keep the printer running smoothly. Following these steps helps your printer last longer and make better prints.

Key Takeaways

- Shake white ink cartridges daily and perform nozzle checks to maintain consistent flow and prevent clogging in printheads.

- Clean printheads and wipe down exterior surfaces daily with lint-free cloths to remove dust and excess ink.

- Conduct weekly inspections of filters, mechanical components, and color profiles to ensure optimal printer performance.

- Perform monthly deep cleaning of internal components, including ink lines, and update firmware for system maintenance.

- Maintain detailed cleaning records and monitor environmental conditions to prevent issues and ensure consistent print quality.

Daily Maintenance Requirements

DTF printers need daily care to work well and make good prints. Start by giving the white ink a good shake - this stops the ink from settling at the bottom and keeps it mixing well.

Clean the printheads regularly to stop them from getting blocked, which can ruin your prints.

Every day, you need to test the nozzles to make sure they're working right and catch problems early.

Keep an eye on ink levels so you don't run out in the middle of a job, which wastes time.

Clean the outside of the printer to get rid of dust and dirt that could get in the way.

When you do these basic care steps each day, your printer will last longer and keep making clear, sharp DTF transfers.

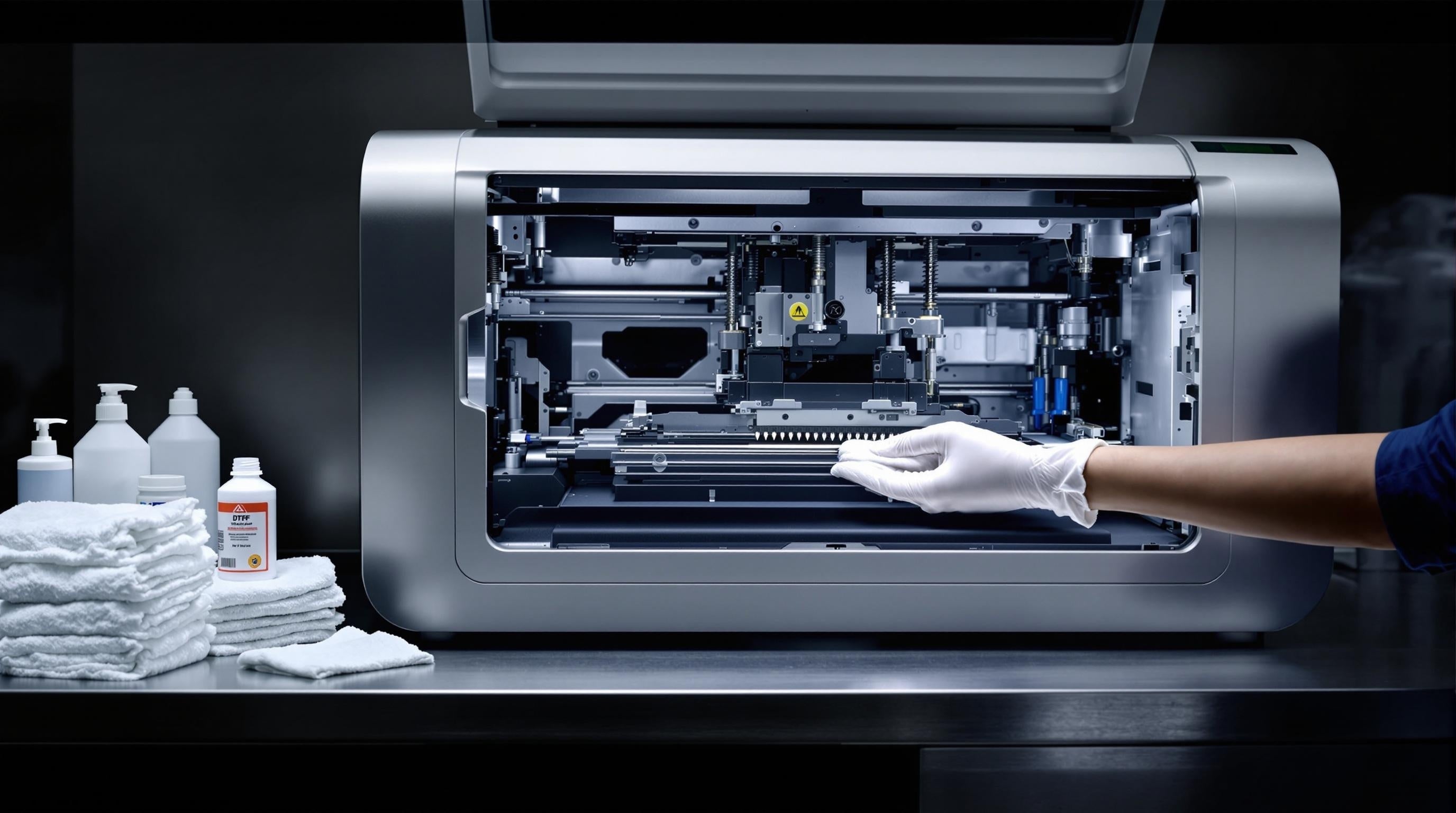

Essential Cleaning Tools

A DTF printer needs specific cleaning tools to keep it working well and lasting longer. The basic cleaning items you'll need include rubbing alcohol (8-16 oz) to clean off ink from sensitive parts.

Microfiber cloths work best for wiping the outside, as they catch dust without scratching the surface. For detailed cleaning, you'll want cotton swabs to clean tight spots, especially near the printheads and where ink cartridges go.

Clean wipes that don't leave bits behind help with everyday cleaning tasks. Several cans of compressed air are needed to blow out dust from inside the printer and its air holes.

Using these tools regularly and correctly helps keep print quality high and makes your printer last longer through good care and upkeep.

White Ink System Care

Proper care of the white ink system is essential for good printing and a longer system life. Shake the white ink cartridge every day to mix the ink properly and keep it flowing well for better print quality.

Clean the printhead regularly to stop ink from building up and keep the system running smoothly. Check the nozzles often to make sure white ink flows correctly and to spot any clogs before they cause printing problems.

Keep ink in a cool, dark place to keep it fresh and working well.

Keep track of all cleaning and care tasks to watch how the system is working and to spot any patterns when problems come up. Taking good care of the white ink system helps catch issues early and keeps print quality steady during all printing jobs.

Print Head Management Steps

Print head care needs a step-by-step plan to keep DTF printers working well. Check nozzles every day to make sure ink flows freely and spot any blocks that could hurt print quality.

Clean print heads once a week to stop clogs and keep them working their best.

Watch the temperature while printing to stop print heads from getting too hot, and shake the white ink daily so it doesn't settle.

If printing problems keep happening, do a deep clean using the right cleaning fluids.

Taking care of print heads this way helps ensure good prints and makes the printer last longer.

When workers follow these care steps in order, they can avoid printer breakdowns, keep prints looking good, and skip costly fixes.

Regular Calibration Procedures

Regular calibration is key to getting good DTF prints. You need to check and fix print alignment every few weeks and run test prints to make sure colors look right before starting big jobs.

To keep your printer working well, you should check its settings match what the maker recommends, especially how much ink it uses and how fast it prints.

The room where you work matters too - you need steady temperature and humidity to keep things working right.

Colors also need attention, so make sure to update your color profiles now and then to keep prints looking the same on different materials.

When you stay on top of these regular checks, your DTF transfers will have better colors and line up correctly, which means fewer mistakes and better results.

Storage and Safety Guidelines

Keep DTF supplies stored correctly to ensure good prints and safe working conditions. Store inks in a cool place between 15-25°C (59-77°F), and keep them out of sunlight to keep colors fresh.

Put ink cartridges in sealed containers so air doesn't get in and block the nozzles. Label all storage boxes and containers clearly to stay organized and avoid mixing up materials.

Keep everything in a dry place since moisture can ruin print quality and make transfers less sticky. When working with inks and cleaning products, always wear safety gear like gloves and masks.

These steps keep workers safe and help maintain DTF supplies in good shape, leading to better prints and a safer workplace.

Ink Level Monitoring

Watching ink levels is key to running DTF printers well. Having the right amount of ink helps avoid work stoppages and keeps print quality steady. Using a digital system to watch ink levels lets you track supplies as you work and warns you when ink runs low.

| Monitoring Task | What to Do | How Often |

| Look at Ink | Check levels | Every day |

| Digital Checks | Watch for warnings | As it happens |

| Use Tracking | Measure how much is used | Every week |

| Supply Count | Check backup ink | Every two weeks |

| Quality Checks | Print test items | Each job |

Checking ink daily and keeping extra supplies on hand makes work run smoother. Writing down how much ink you use helps predict future needs, so you can buy more before running out. This careful way of managing ink keeps printing jobs going and ensures good results every time.

Troubleshooting Common Print Issues

Print problems in DTF printing can be fixed faster when you follow clear steps to find and fix the issue. Taking care of your printer regularly helps it work its best.

Watch out for these common problems:

- Lines or stripes in prints from blocked print heads or nozzles that aren't lined up right - check and clean nozzles right away

- Wrong colors or fading when ink is running low or cartridges have problems

- Ink marks or smears when the ink hasn't dried properly or pressure settings are wrong

- Uneven print quality that needs to be tracked to spot patterns

Setting up a regular cleaning plan and keeping up with basic care helps stop these problems before they start.

Check printer parts often, update the printer software when needed, and write down the steps you take to fix problems. This careful approach helps your printer last longer and keeps your work flowing smoothly.

Quality Control Best Practices

Quality checks help DTF printing shops make great prints that look professional every time. Using color profiles helps create bright, true colors, while regular print checks make sure everything stays on track.

Good upkeep means cleaning printer heads often, checking that parts line up right, and doing test prints before big jobs.

Color settings need regular adjustments to keep prints looking their best. Keeping a record book of each print job's details helps catch problems early and keeps the printer working well.

Asking customers what they think helps printing shops get better, making sure prints keep meeting high standards.

Preventive Maintenance Schedule

A good preventive maintenance schedule helps keep DTF printers working well and printing with high quality.

Regular maintenance stops problems before they start and helps avoid expensive repairs.

- Weekly Tasks: Clean the printer regularly by shaking white ink cartridges, cleaning printheads, and checking if nozzles work properly.

- Monthly Tasks: Check inside parts and wipe off ink splashes, clean away dust and dirt that can hurt print quality.

- Quarterly Tasks: Do deep cleaning, look at all parts, update printer software, and adjust printer settings.

- Annual Tasks: Get a professional to check the whole system.

Keep clear records of all maintenance work to track how the printer is doing and spot any issues that keep coming back.

This step-by-step approach to maintenance helps the printer last longer and makes sure your DTF transfers always look good.

Frequently Asked Questions

What Is the Maintenance on a DTF Printer?

DTF printer maintenance consists of wiping print heads clean, checking ink levels and quality, looking over printer parts, doing regular cleaning tasks, and fine-tuning settings based on room conditions to keep the printer running well and avoid problems.

How to Take Care of DTF Printing?

Keep an eye on ink levels, clean printer heads regularly, adjust printer settings as needed, check colors are correct, and make sure the temperature is right when printing. Keep printer software up to date and fix any problems to work well with different materials.

Should I Leave My DTF Printer on All the Time?

You should turn your DTF printer off and on regularly to keep it running well. Keeping it on all the time uses more power, costs more money, and can wear out parts faster. It might also make your prints look worse over time and shorten how long your printer lasts.

How Often Do You Need to Use a DTF Printer?

You should run your DTF printer at least once every 2-3 days to keep it working well. Using it regularly helps make sure your prints look good, stops ink from getting stuck, and keeps the transfers coming out right.

Conclusion

At Perfecpresshtv.com, we know that DTF printers need careful daily cleaning, proper white ink care, and regular print head checks. Good printer care includes basic calibration, keeping track of ink levels, and fixing small issues before they become big problems. Following a detailed cleaning schedule and quality checks helps keep your printer running smoothly with fewer breakdowns, making your DTF transfer work more reliable and efficient.