To get great DTF transfer results, you need to keep your workspace at the right temperature (75-80°F) and humidity (55-75%). Use good-quality transfer films, mix your inks correctly, and apply adhesive powder carefully. Check your ink thickness, film quality, and how well transfers stick to make sure everything works well. Keep your materials in a cool, dark place to stop moisture from ruining them and to keep the film in good shape. Setting up basic quality checks and taking care of your equipment will help you become an expert at DTF printing.

Key Takeaways

- Apply DTF transfers in a controlled environment of 75-80°F with 55-75% humidity for optimal adhesion and durability.

- Load transfer films carefully, ensuring they're free from dust and debris before printing to prevent quality issues.

- Use the correct amount of adhesive powder, spreading it evenly across the printed design for consistent bonding.

- Perform test prints and pull tests on sample materials before large-scale production to verify transfer quality.

- Monitor ink thickness and film surface quality throughout the printing process to maintain consistent results.

Getting Started With DTF Printing

Starting DTF printing requires the right setup steps to get good results.

First, take out and put together your DTF printer, install the needed software, and connect everything. Fill the ink tanks with good quality ink to make sure your prints look their best.

Next, load your transfer sheets correctly and put adhesive powder in the dryer section, as this helps the prints stick well.

Keep your work area at the right temperature (75-80°F) and humidity (55-75%). The way the starch and PET film work together makes a big difference in how well your prints turn out and last.

Mix your ink and solvent in the right amounts, then do a test print to check if everything's working right. Start taking care of your equipment right away with regular cleaning and checks to keep getting good prints.

Essential Tools and Materials

Essential tools and materials for DTF transfers need to be chosen with care. The most basic item you'll need is good transfer film, which comes in regular plastic or eco-friendly versions.

You'll also need proper tools to apply the transfers and good design software to create your artwork.

Taking care of your tools and materials is just as important as having them. Keep your transfer films in a cool, dark place away from moisture to make them last longer.

You'll want tools to check powder amounts and test ink quality to make sure everything works well. It's also important to have equipment that keeps your workspace at the right temperature (75-80°F) and humidity (55-75%), as this affects how well your transfers turn out and how long they last.

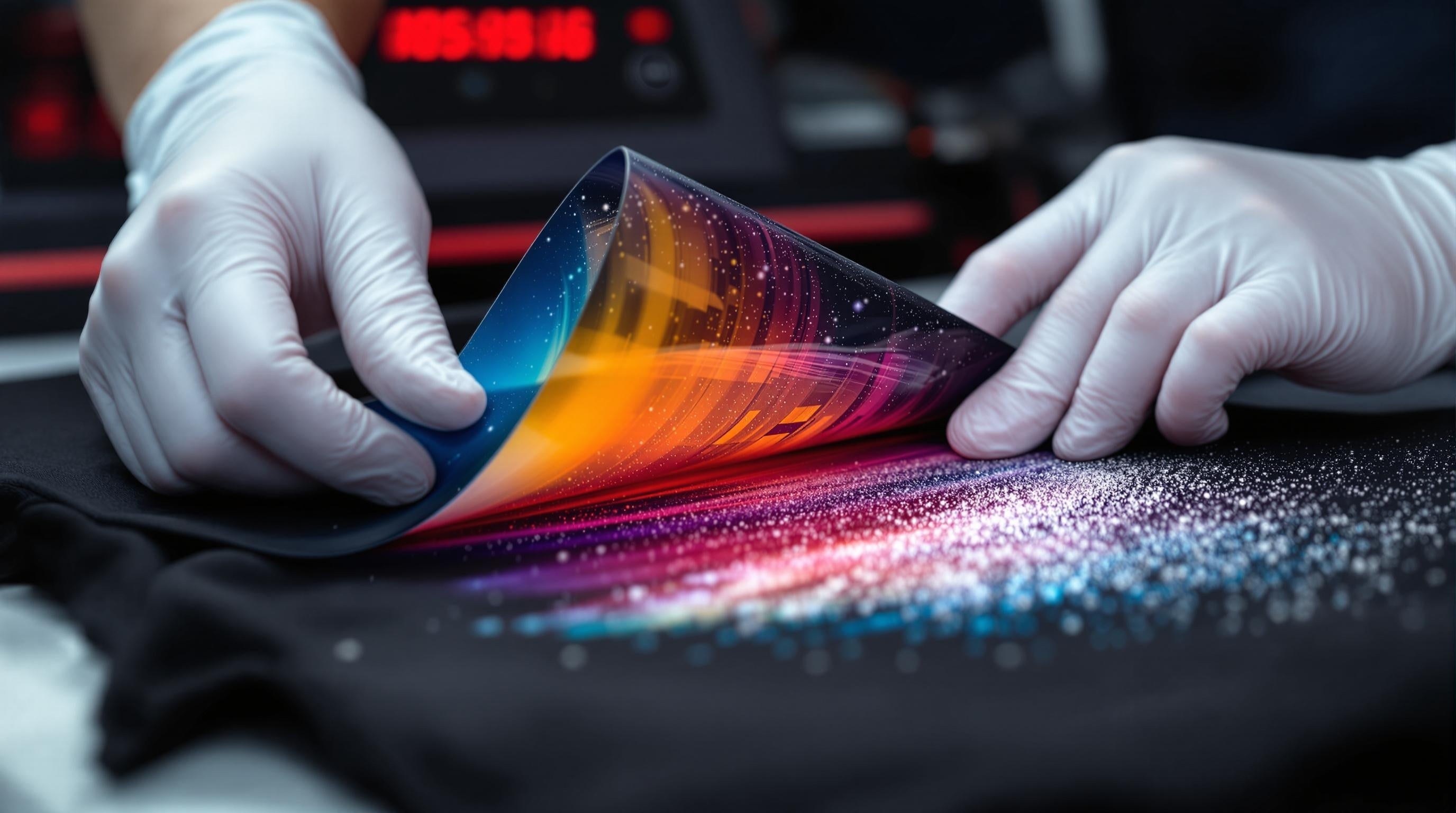

Understanding Transfer Film Properties

Getting to know DTF transfer films is key to getting great results. These films are made of PET (a special type of plastic), which affects how well ink sticks to them and how long the prints last.

Having a good film surface is very important. The size of starch bits on the film matters - smaller bits help the prints go on more smoothly and stick better.

The room where you work needs to be just right: keep it between 75-80°F with humidity at 55-75%. This helps the ink flow well and makes sure everything sticks properly. You must keep the film clean, as dirt or dust can ruin your prints.

Some films come with heat-activated glue and need special care. When you know how different films work, you can pick the right one and use it correctly to make your projects turn out well.

Optimal Environmental Setup

A well-controlled workspace is key for getting the best results with DTF transfer films. You'll need the right mix of moisture in the air (55%-75%) and room temperature (75-80°F) to make sure the prints stick well and look good.

| Environmental Factor | Acceptable Range | Critical Impact |

| Humidity | 55%-75% | Adhesion Quality |

| Temperature | 75-80°F | Film Stability |

| Storage | Cool & Dark | Material Integrity |

| Air Quality | Low Dust/Pollutants | Print Durability |

Using climate control equipment helps keep these conditions steady. Keep your transfer films in a cool, dark place to protect them from moisture and sun damage. Clean air with little dust helps your prints last longer. When these conditions are right, the materials bond better during printing, which means your finished products will be stronger and look better.

Print Design Preparation Guidelines

Good print design starts with getting the basics right. You need to check if your artwork is the right size and clear enough to make sure your DTF transfers look sharp and clean.

After that, you need to set up your printer correctly, especially how much ink and solvent you use, since this affects how well the design sticks and how bright the colors look.

To get the best results, you need to test and adjust your designs step by step. Pick DTF transfer films that match what you're trying to make, keeping in mind how thick they are and how well they stick.

Use the right tools to spread powder evenly over your design. Make test prints often to check quality and fix any problems with your design settings or how you apply the transfer.

This careful way of working helps save materials and leads to better prints by paying attention to both technical details and making sure materials work well together.

Advanced Application Techniques

DTF transfers work best when using proven methods that get great results. Getting the hot melt powder just right is key - using a spinning process spreads the powder evenly and wastes less material. Mixing the right amount of ink and liquid helps avoid problems and makes better transfers.

Letting transfers dry at normal room temperature while stirring the mixture helps spread curing materials evenly, making prints last longer. Taking good care of equipment is important - this means checking printer settings, watching powder levels, and testing the mixture quality.

The work area needs the right conditions too. The air should be slightly damp (55-75% humidity) and warm (75-80°F). When these conditions are right, the materials work together better, giving reliable, high-quality transfers every time.

Quality Control and Testing

Quality control for DTF transfers needs careful testing and checking during each step of making them.

Good testing helps make sure every transfer comes out well and lasts long.

Main testing steps include:

- Keeping track of room moisture (55%-75%) and heat (75-80°F) when making transfers for the first time.

- Often checking how thick or thin the inks are to fix problems before they mess up the printing.

- Looking closely at transfer films to spot problems like bubbles or uneven coating.

- Testing how well transfers stick by measuring how hard they are to pull off.

These steps, along with wash testing to check if colors stay bright and transfers stay stuck on, make up a complete testing plan that helps create DTF transfers customers can count on.

Maintenance and Storage Protocols

Keeping DTF transfer films in good condition requires careful handling and storage throughout production. Films need to be kept in cool, dark places where moisture levels stay below set limits.

Work areas should be kept at 75-80°F with moisture levels between 55%-75% when applying films.

Tools must be regularly checked and adjusted, including mixing equipment and powder amounts, to keep quality steady.

Regular checks of materials help catch any dirt or damage in stored films.

Following proper storage rules and checking work conditions regularly helps keep films in good shape and ensures prints stick well every time they're made.

Frequently Asked Questions

How to Properly Apply DTF Transfers?

Wipe the surface clean, spread the powder coating evenly, press with heat at 320°F using firm pressure for 10-15 seconds, let it cool down a bit, then gently pull off the film backing to finish.

What Are the Heat Press Settings for DTF Transfer?

For best DTF printing results, heat your press to between 320°F-385°F. Press down with medium force for 10-15 seconds. Keep the room's moisture level between 55%-75% while working.

What Is the DTF Printing Technique?

DTF printing works by putting designs on special film using a digital printer, then adding sticky powder on top. When heat and pressure are applied, the design moves from the film to the fabric while keeping its bright colors.

What Are the Pros and Cons of DTF Printing?

DTF printing makes great-looking prints that last long and works well on many different materials, while getting the job done fast. On the downside, you need to spend a lot of money to start, keep the workspace at the right temperature and humidity, and know exactly what you're doing to get good results.

Conclusion

DTF transfer film application doesn't have to be complicated when you follow the right steps. At Perfecpresshtv.com, we focus on teaching easy-to-follow techniques for handling materials, setting the right temperatures, and checking print quality. By taking care of your equipment and storing materials properly, you'll get great results on your textile prints every time. With our proven methods from Perfecpresshtv.com, you can create professional DTF transfers that look amazing and last long.