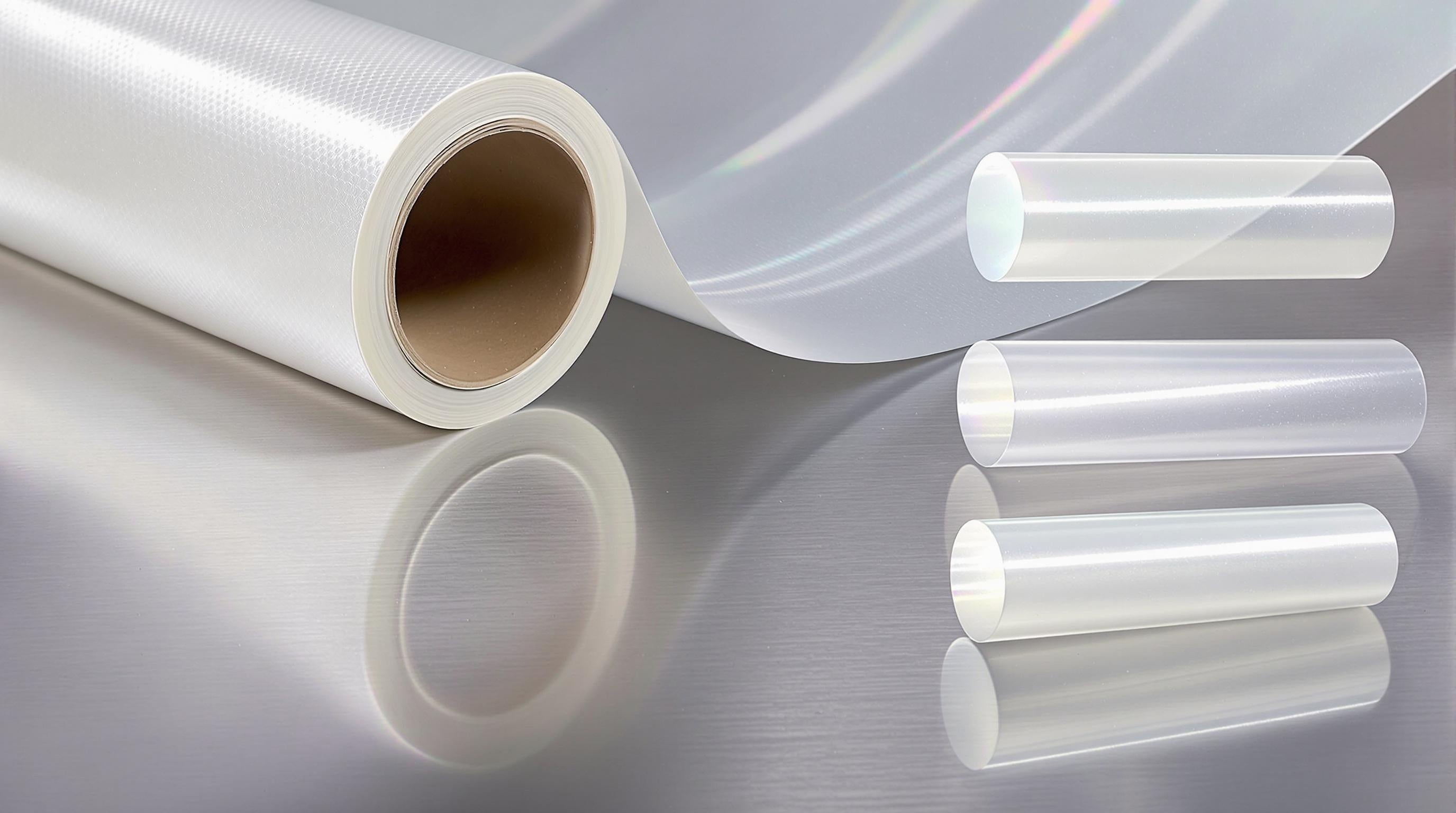

DTF transfer films come in four main types: cold peel, hot peel, matte, and glossy. Cold peel films need to cool down before you can take them off and work best with fine details. Hot peel films can be pulled off right away, making them great for big jobs. Matte films have a soft, non-shiny look that helps prints show up well on many types of fabric. Glossy films make bright, shiny prints that look best on light-colored materials. Films can be thin (75) or thick (100), which changes how long they last and how good the prints look. You can also get special films that sparkle, shine like metal, or glow in the dark. Knowing these differences helps you pick the right film for your project and get the results you want.

Key Takeaways

- Cold peel DTF films are ideal for detailed designs and intricate patterns, requiring cooling before removal for optimal results.

- Hot peel films enable immediate removal after application, making them perfect for high-volume production and quick turnaround projects.

- Matte finish films provide superior print quality on various fabrics while reducing glare for a professional appearance.

- Glossy films create vibrant, eye-catching designs particularly effective on light-colored fabrics and fashion apparel.

- Specialty films like glitter, metallic, and glow-in-the-dark offer unique decorative effects for custom clothing and promotional items.

Understanding DTF Film Core Properties

DTF film must have the right features to work well in printing. The film's special coating helps it take in ink properly and transfer it smoothly to fabrics.

White or opaque films work better than clear ones, as they hold ink better and stop it from bleeding through to the material below.

These films are made to stay flat and strong when heated during transfer, which stops problems like warping or bending. For special designs on clothing, there are different types of DTF films, like ones with glitter, shine, or glow effects, that still work as well as regular films.

The film's ability to take in ink and handle heat means you get good results on many types of fabric and different designs.

Common DTF Film Varieties

DTF film comes in four main types: cold peel, hot peel, matte, and glossy, each made for different kinds of printing. When using DTF printing, you need to pick the right film based on the fabric and the look you want. Cold peel DTF film needs to cool down before you can peel it off, while hot peel DTF film can be removed right after pressing, making work faster.

| Film Type | Key Features | Best Applications |

| Cold Peel | Cooling required | Detailed designs |

| Hot Peel | Immediate removal | High-volume production |

| Matte | Double-coated, frosted | High-quality prints on various fabrics |

| Glossy | Single-coated, smooth | Vibrant designs on light fabrics |

Special DTF films also include glitter, reflective, and glow-in-the-dark options, giving you more creative choices while still working well for transfers. Each type has its own benefits in terms of how it looks, how long it lasts, and how you use it.

Material Compatibility and Applications

DTF transfer films work well on many types of fabrics, making them a flexible choice for printing. You can use them on basic materials like cotton and polyester, as well as nylon, canvas, and denim, which means they're great for making all kinds of custom clothing.

These films work differently depending on the fabric you choose, and there are special types for specific needs. Cold peel films are best for small, detailed designs, while opaque films make colors stand out, which is perfect for eye-catching promotional wear.

You can also get special effects with glitter and metallic films to add shine and texture to your designs. Because DTF films work well on both light and dark fabrics and can be used on so many materials, they're a reliable choice for making custom clothing and decorative items.

Performance Factors and Selection

Choosing the right DTF film means looking at how well it performs in different ways to get good prints that last. The film needs to soak up ink well and handle heat properly to stop problems like curling when the design is being pressed onto fabric.

Main things to look at when picking DTF film:

- How thick the film is (75 film works for everyday use, 100 film is better for top-quality work) affects how good the print looks and how long it lasts.

- Whether you can peel the film off hot or cold makes a difference in work speed - hot peel lets you remove it right after pressing.

- Some films work better with certain inks to create different looks, like shiny, flat, or glowing finishes.

You need to pick film that works well with your printer and matches what you want to make. This helps make sure the film and your printing needs fit together well and keeps your work quality steady.

Advanced DTF Film Technologies

Film technology has made big steps forward, giving DTF transfers new and better ways to work. Today's DTF films come with special features like glitter, metallic shine, and glow-in-the-dark options that create eye-catching designs.

The coating on these films is key to their success. Good coatings help the ink sink in better, which means clearer details and brighter colors. Some films can be peeled off right away when they're hot, while others need to cool down first - this helps when working on detailed designs.

Matte films cut down on shine, making prints look crisp and clean. All these films can handle high heat, so they stay strong during the heating process.

These improvements have opened up many new ways to use DTF printing while keeping the quality and long-lasting results that users need.

Frequently Asked Questions

What Is the Best File Type for DTF Printing?

For DTF printing, you can use either vector files (like SVG and AI) which give you perfect sharpness at any size, or clear picture files like PNG/TIFF that are high-quality (at least 300 DPI) with see-through backgrounds. Both options work well when using DTF printing software.

What Are the Different Types of DTF Paper?

DTF paper comes in several forms: cold and hot peel films that come off differently, shiny single-sided and dull double-sided papers, special types with glitter, foil, or light-catching finishes, and see-through or solid films that are 75-100 microns thick. Each type works best for certain kinds of printing jobs.

How to Choose a DTF Film?

Pick DTF film by checking how thick it is, how well it sticks, if it works with your printer, and how long it lasts. Think about how smooth or rough you want it, what colors you need, where you'll keep it, and how you'll put the design on your items to get good prints that stay nice for a long time.

What Is the Best Material for DTF Transfers?

The best DTF films are made from polyethylene with special coatings that help ink stick well. These films make transfers that last long, show bright colors, and bond strongly to fabrics. They also print clear, detailed designs and work well on many types of clothing.

Conclusion

DTF transfer film technology keeps getting better, offering more options for different fabric needs. At Perfecpresshtv.com, we know that picking the right film type depends on important things like what material you're printing on, where it will be used, and how long it needs to last. New film formulas now offer better durability, can handle more washes, and stretch better than ever before. To get the best results in commercial printing, it's important to match the right film properties with how you'll use it.