DTF (Direct to Film) printing helps make small batches of designs quickly by using clear films and special inks that can handle heat. You'll need to spend between $1,500 and $7,000 on equipment to start, but you won't have setup costs later and you'll waste less materials thanks to a smoother work process. Each print needs about 12-15 seconds at 280°F, and the designs stay good for more than 50 washes on many different types of fabric. The materials you need include transfer film, which costs $1.50-$3.00 per square foot, and ink at $80-$120 per liter. You can print several designs at once to save time and work better. Learning how DTF works can help you find more ways to make small batches faster and earn more money.

Key Takeaways

- DTF transfers provide high-quality, durable prints on various fabrics with minimal setup time and equipment costs starting at $1,500.

- Multiple designs can be printed simultaneously on one sheet, reducing material waste and maximizing efficiency for small orders.

- Equipment requires special films ($1.50-$3.00/sq ft), sticky powder adhesives, and quality inks ($80-$120/liter) for optimal results.

- Heat press application at 280°F for 12-15 seconds creates transfers that withstand over 50 washes without fading.

- Small batch production benefits from eliminated setup fees, reduced material waste, and simplified workflow for increased profitability.

Understanding DTF Transfer Basics

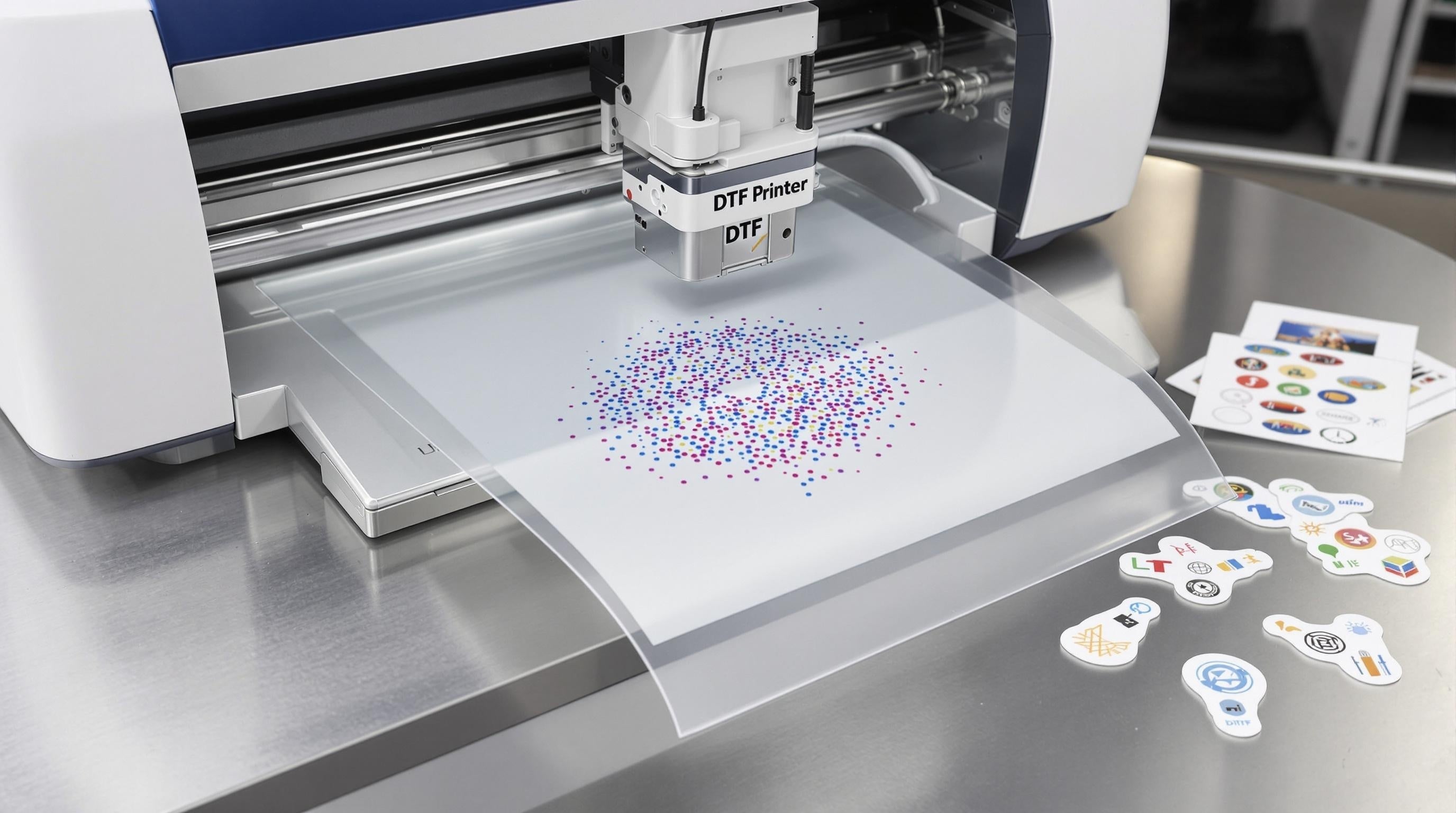

DTF transfer printing is a new way to put designs on clothes that creates sharp, colorful prints in two main steps. This printing method uses safe inks to make transfers that stick well to many types of fabric, like cotton, polyester, and mixed materials.

The printer first puts your design onto a special clear sheet. Then, this sheet is pressed onto the clothing using heat at 280°F for 12-15 seconds.

When done right, the design stays on firmly and can last through more than 50 washes without fading or peeling. DTF transfers work great for printing small numbers of items, give bright colors, and feel soft on the clothes, making them perfect for today's clothing needs.

Cost Analysis for Small Batches

Looking at DTF printing costs for small batches shows clear benefits compared to older printing methods.

Getting started needs $1,500 to $7,000 for DTF equipment, which many small businesses can handle.

Running costs stay low, with transfer film costing $1.50 to $3.00 per square foot and ink running $80 to $120 per liter.

DTF printing saves money by cutting out setup fees and using only the materials needed for each job.

Small batch printing becomes more profitable because the simple work steps mean less time spent on each order.

Equipment and Material Requirements

Starting DTF printing needs specific tools and supplies. You'll need to spend between $1,500 and $7,000 at first to buy DTF printers and a heat press. This setup lets you print on many types of fabric, like cotton and polyester mixes, so you can make custom designs.

To run a DTF printing business, you'll need:

- DTF films that cost $1.50-$3.00 for each square foot

- Special sticky powders to make prints stay on fabric

- Good quality ink that costs $80-$120 per liter

- Design patterns that fit DTF sheet sizes

When picking equipment, think about how many items you want to print and remember to count the costs of ink and supplies you'll need later.

Setting up your artwork size correctly and using the right DTF sheet sizes will help you get the best quality prints and work smoothly.

Production Workflow Optimization

To make DTF production work better, businesses need to plan their steps carefully and use their tools wisely. Using the right settings on DTF machines helps cut down on human work while keeping prints looking good. This works really well for making small amounts of prints and custom designs.

A smart way to work is to put many designs together on one sheet. This saves materials and makes the whole process run faster. The prints can dry quickly, which means small orders get done without long waits.

Having a clear plan for each step means less time spent getting ready between jobs, making it easier to switch from one task to another. When production is set up this way, DTF transfers get done quickly and still look great, even for special custom orders.

Quality Control Best Practices

Quality control steps in DTF transfers help create great results and reduce mistakes. Good quality checks start by making sure the ink sticks well and the print looks clear before use.

Use printer settings of 300 DPI or higher with PNG files for best results. When applying heat, use Teflon sheets to spread the heat evenly and keep the design clean.

- Check prints for quality and correct colors before use

- Watch heat press settings and pressure

- Look over finished products to find spots that need more pressing

- Keep track of mistakes and fix problems right away

Following these quality steps makes customers happy by giving them good DTF transfers every time.

This careful way of working wastes less material, keeps quality high, and makes it easy to fix any problems that come up during production.

Pricing Strategies That Work

DTF transfer businesses can make more money by setting smart prices and maintaining high quality. When deciding prices, owners need to look at their costs carefully - ink runs $80-120 per liter, and film costs $1.50-$3.00 per square foot.

Small business owners should offer better prices for bigger orders while still making enough profit. To stay in business, they need to figure out their real costs based on order size, worker time, and materials used.

For small orders, focusing on special markets with unique designs lets businesses charge more. The best approach is to set different price levels that keep prices fair but profitable, while keeping track of costs and making changes based on market changes and how well production is working.

Scaling Your DTF Business

Growing a DTF business needs smart planning to make work run smoothly and get more done. Using fast setup times and quick delivery helps handle small jobs while keeping costs down.

Printing multiple designs on one sheet and offering better prices for bigger orders helps work flow better and gets customers to order more custom clothing.

- Check and fix pricing often based on supply costs and how well you're producing

- Print multiple designs at once to get more done and waste less

- Keep up with new tools and methods to stay ahead

- Find special customer groups who want unique designs

To grow your DTF business well, you need to match how much you can make with what customers want, while making sure prints last through many washes.

Checking how work gets done and how well your machines run helps keep your business growing and making money in the custom clothing market.

Frequently Asked Questions

How to Do Direct to Film Transfers?

Print your design onto special film sheets with the right colors and settings. Put adhesive on the design, make sure your fabric will work well with it, then use the right heat and timing to transfer it cleanly onto your material. Follow each step carefully to make sure the design sticks and stays on.

What Machine Do You Need to Make DTF Transfers?

You need a DTF printer that handles colors well, basic design software that works with it, and a system that puts glue on evenly. You'll also need a heat press that lets you adjust settings to make transfers at the right speed for your needs.

What Kind of Printer Do I Need for DTF?

You'll want a special DTF printer that prints very clearly (at least 300 DPI), uses color and white ink, takes care of itself with basic maintenance, and works with design software. These printers typically cost from $1,500 to $7,000.

Can You Use DTF Transfer Paper in a Regular Printer?

No, you can't use DTF transfer paper in regular printers. You need special DTF printers to make the ink stick properly, get the right colors, and add the white base layer that makes your designs look professional.

Conclusion

Direct-to-film transfer technology offers a practical solution for small-batch garment printing, making it easier and more affordable when done right. At Perfecpresshtv.com, we help businesses streamline their workflow, maintain quality standards, and set smart pricing to grow steadily. By using the right equipment, materials, and production methods, DTF printing helps businesses stay competitive while creating custom apparel that meets each customer's needs.