DTF printing can run into several problems like wrong heat levels, uneven ink, and prints not sticking well. To fix these issues, keep your heat press between 320°F-350°F, clean your printer heads often to keep ink flowing smoothly, and make sure you put on adhesive powder correctly. Start with clear, sharp images (300 DPI) and wash fabrics before printing. Use the right pressure (40-60 psi) and press time (10-15 seconds) to avoid failed transfers. Keep your work area at 77°F and 60% humidity for the best results. Taking care of your equipment and picking good materials helps create high-quality DTF prints. Following exact steps helps make prints that last longer and look clearer.

Key Takeaways

- Poor ink adhesion can be resolved by maintaining proper heat press settings between 320°F to 350°F and pressure at 40-60 psi.

- White ink smudging is prevented through regular printhead cleaning and ensuring prints are completely dry before transfer.

- Film wrinkles during transfer are eliminated by proper film loading and consistent temperature throughout the process.

- Print peeling issues are solved by using adequate adhesive powder and ensuring fabrics are pre-washed to remove oils.

- Uneven color output is corrected through proper printer calibration and maintaining optimal environmental conditions of 60% moisture and 77°F.

Understanding DTF Printing Fundamentals

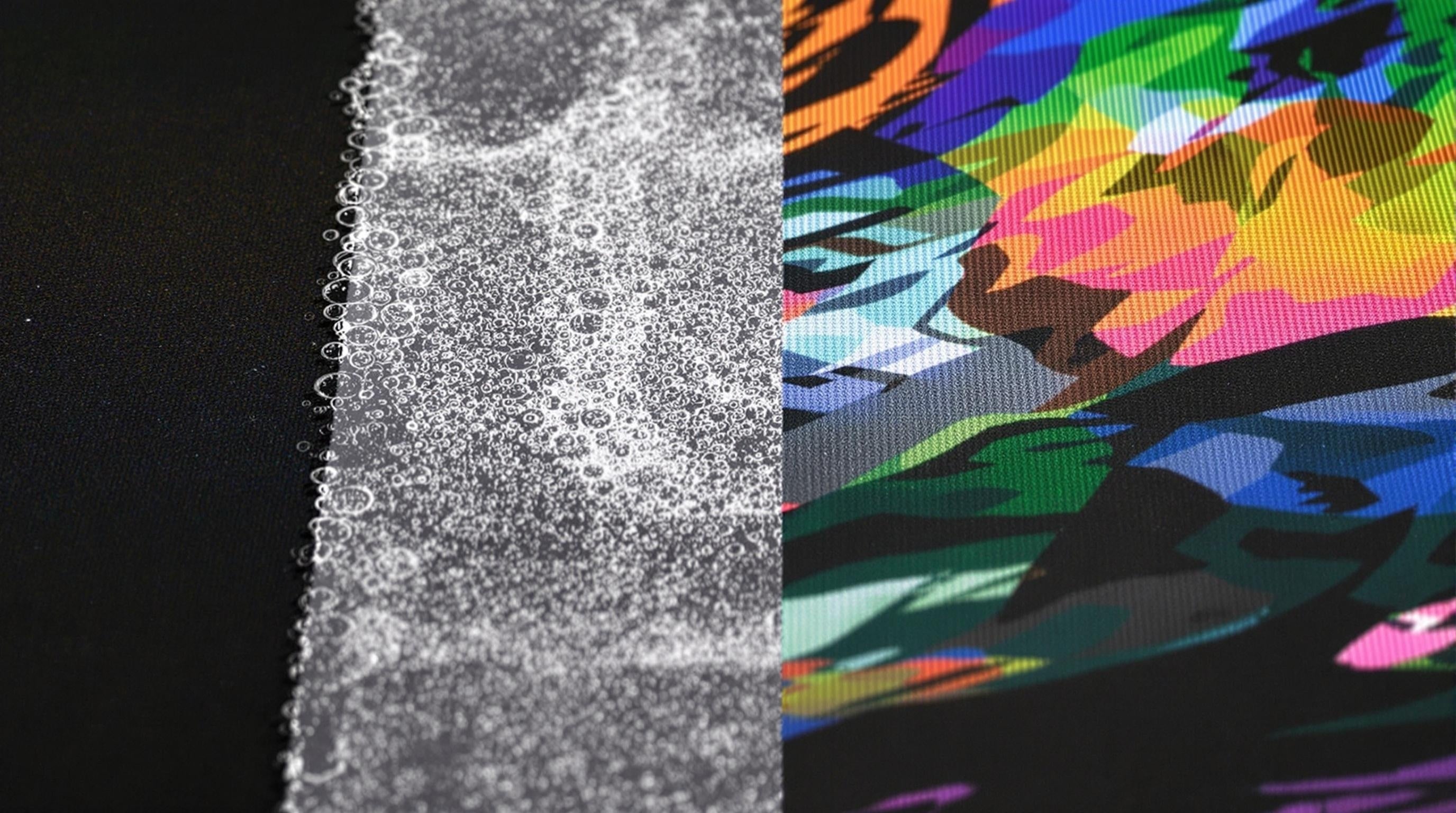

DTF printing is a new way to put custom designs on clothing by using special film and heat. To make it work well, you need to know how the film, white ink, and heat press work together.

The first step uses white ink printed onto special film, which helps make colors look bright and clear, especially on dark clothes.

Getting the ink to stick properly depends on using the right heat and pressure when pressing the design onto fabric. To get good results every time, you need to control these settings carefully and think about what kind of fabric you're using.

When you understand these basic steps, you can avoid problems like designs that peel off, transfers that don't work properly, or prints that wear out too quickly.

Ink Quality and Coverage Issues

Getting good DTF prints starts with the right ink quality and coverage. You need to control how much ink flows and use the right printer settings to get even coverage and good transfers. Clean your printheads often and watch how much ink you're using to stop excess ink from spreading and ruining prints.

| Issue | Solution |

| Ink Smudging | Let prints dry fully before transfer |

| Uneven Coverage | Fix printer settings and ink flow |

| White Ink Issues | Mix ink often and clean nozzles |

| Bleeding | Check and adjust ink amounts |

White ink needs extra care because it must be solid and bright on dark fabrics. To make this happen, you need to take good care of the white ink system. Making sure prints are completely dry before transfer helps the ink stick better and stops smudging, giving you strong, clean DTF prints that last.

Film Transfer Complications

Film transfer problems can happen during DTF printing and affect how well the design turns out. The print may not stick properly if the heat press isn't set correctly, and the film can get wrinkled if it's not loaded the right way or if the tension isn't even during transfer.

To avoid these problems, printers need to keep the heat steady throughout the process. Changes in temperature can make prints look uneven. It's important to check the film for any dirt or dust before starting, as these can cause flaws in the design.

Getting rid of air bubbles is also key for good transfer quality. This means using the right methods with the squeegee and peeling the film back slowly. When printers pay close attention to these steps, they're more likely to get good transfers that stick well and look complete.

Print Resolution and Clarity

Getting good print quality in DTF transfer printing means paying close attention to several key things.

Starting with images that are at least 300 DPI helps create crisp, clear prints. You need to set up the printer correctly and make sure the printheads are lined up well to avoid fuzzy or distorted images.

Keeping up with basic maintenance, like cleaning the printheads regularly, helps the ink flow smoothly and prevents printing flaws.

The printing speed needs to be just right since going too fast or too slow can affect how well the details show up and how the ink spreads.

It's important to check room conditions and run test prints often to catch and fix any problems early.

Adhesion and Durability Challenges

Keeping prints firmly attached and making them last are two main challenges in DTF printing that need close attention. Good ink sticking depends on using the right amount of adhesive powder and making sure fabrics are clean and ready before printing.

To get the best grip, you need the right heat, pressure, and time when pressing the design onto fabric. Taking care of printer parts, especially where ink flows through, stops clogs that can hurt print quality and how well it sticks.

The type of fabric you choose matters too, since different materials take ink and hold it differently.

Checking and setting up heat press machines regularly keeps temperatures steady, while testing prints helps catch and fix problems before they affect your work. These steps help prevent prints from coming loose or not transferring fully.

Color Management Best Practices

Color control is key for good DTF printing. To get colors right, you need to set up your printer correctly and use good color settings. Keep your printing area at the right warmth and moisture levels to stop colors from changing.

|

Process |

Challenge |

Solution |

|

Calibration |

Color drift |

Regular printer adjustments |

|

Testing |

Color matching |

Frequent test prints |

|

Environment |

Climate variation |

Temperature monitoring |

For the best prints, use color control tools and software. Print test sheets often to catch problems early. Pick good-quality inks made for DTF printing - this helps get the right colors and keeps prints looking the same on different fabrics.

Equipment Maintenance Guidelines

To keep DTF printing equipment working well, you need to follow key care steps.

Clean the printheads every two weeks to stop them from getting blocked, especially when using white ink which tends to clog more easily.

Check printheads monthly and test how well the ink flows.

Keep the room at the right moisture level (60%) and temperature (77°F) so the ink stays in good shape.

Set up your printers regularly to make sure colors look right and prints line up properly on the fabric without hitting or shifting.

Use good quality inks and make sure your materials work well together.

When you stick to these care steps, you'll have fewer printing problems, your equipment will last longer, and your prints will look better.

Temperature and Pressure Settings

Temperature and pressure must be set correctly for DTF transfer printing to work well.

For best results, keep the temperature between 320°F and 350°F (160°C to 177°C) - this helps the ink stick and dry properly. The pressure should stay between 40-60 psi while using the heat press.

Press the design for 10-15 seconds, but you might need to change this time depending on how thick your material is and what kind of ink you're using.

Check your heat press often to make sure it's giving the right temperature and pressure. If the pressure is too low, the design might peel off. If it's too high, it could damage your material or make the design look wrong.

Keep an eye on these settings and take good care of your equipment to get the best prints.

Fabric Selection and Preparation

DTF printing works best when you pick the right fabric and prepare it well.

Choose fabrics like pure cotton or poly-cotton blends that work well with DTF transfers. Always wash your fabric first to get rid of any oils or coatings that might stop the transfer from sticking properly.

For prints that use white ink, stick to light-colored fabrics to make sure your colors look bright and clear, since dark fabrics can make prints look dull.

Test your fabrics before starting big jobs to see which ones give you the best results. Pick fabrics with tight, close-knit fibers to keep your prints sharp and prevent them from getting distorted.

Taking care to pick and prep your fabric the right way helps avoid common printing problems and leads to better prints every time.

Frequently Asked Questions

What Are the Problems With DTF Printing?

DTF printing comes with several issues: the inks must match well with the system, getting the right heat press settings can be tricky, and film quality can vary between batches. Other problems include putting on the sticky powder evenly, setting up the printer correctly, and keeping colors bright over time. Users also struggle with picking the right materials to print on, timing the transfer process properly, keeping their equipment in good shape, and fixing problems when things go wrong.

Why Is My DTF Transfer Not Working?

DTF transfer problems usually happen when your printer isn't set up right, the heat isn't at the right level, the film doesn't stick well, or you're not pressing hard enough. To make your transfers work better, clean your equipment regularly, make sure the ink dries properly, and get your artwork ready the right way.

Why Is My DTF Print Peeling Off?

DTF prints can peel off when the surface isn't cleaned well, the heat press isn't set right, the ink is too thick or thin, or there isn't enough glue. Make sure you're using the right heat level, check if your fabric works with DTF, and follow the steps needed to make the print stick well.

Why Is My DTF Transfer Cracking?

DTF transfers usually crack when the heat press temperature isn't right, when you don't put the adhesive powder on correctly, or when the print hasn't fully dried. Low-quality ink and using the wrong type of fabric can also make your prints more likely to crack and wear out quickly.

Conclusion

DTF transfer printing requires careful attention to get right, but most common issues have straightforward solutions. Managing ink density, setting correct temperatures, keeping equipment in good shape, and using quality materials from trusted suppliers like Perfecpresshtv.com help avoid typical problems. Regular quality checks and following standard steps during printing will ensure your transfers look great and last long. With proper maintenance and the right supplies, you can consistently produce durable, professional-looking DTF transfers for commercial use.